Fool Proof Application

- A product configuration that guides the sequence of tasks through images and prevents mistakes by workers.

- DPC Touch lock the driver when it is not in the working position to prevent mistakes.

- DPC Touch guide fastening sequence by GUI image.

- Bit socket tray control what bit to use.

- Position arm find driver position and reduce worker stress.

- Scanning a barcode automatically switch the order of operations.

1. DPC TOUCH

DPC TOUCH (Position Controller)

DPC TOUCH controls the position to enable error-free operations.

The position encoder can detect the position of the driver with precise resolution. DPC TOUCH also show the sequence of operations in an image, enabling accurate operation.

DPC TOUCH lock the driver when it is not in the working position to prevent mistakes.

It can save data to SD-Card.

Main Feature

- Visualization of assembly process with graphical instructions

- Data save in SD memory card

- Logical I/O’s for workstation automation

- Positioning accuracy : 0.09° for angular encoders <0.5 mm for linear encoders>

- 12 inputs and 12 outputs with assignable functions

- 7” LCD Touch screen, 800 x 480 px

- 4 channels, 0…5V. Analog position encoders

- Adjustable for each position and for each axis

- Smart tolerance detection feature

- All tool with signals – electric or pneumatic

- Min required signals: «Fastening OK», «Tool Lock»

- 255 jobs x 255 steps x 99 positions per fastening step

Product specification

- Process and sequencing Visualization

- Self teaching sequencing

[Interface port]

| Input power | DC24V, 1A AC 100-240V / DC 24V adaptor is provided |

| Dimensions | 202(W) x 128(H) x 38(D) mm |

| Weight | 0.55 kg |

| Screen | 7” LCD Touch screen, 800 x 480 px |

| Graphical interface | Visualization of assembly process with graphical instructions |

| Inputs and Outputs 24V | 12 inputs and 12 outputs with assignable functions Logical I/O’s for workstation automation |

| Analog encoders | 4 channels, 0...5V |

| Memory card | Removable SD card, 8Gb |

| Total jobs memory | 255 jobs with open structure |

| Total positions memory | 255 jobs x 255 steps x 99 positions per fastening step max 100 steps of the same type in one job |

| Positioning accuracy | 0.09° for angular encoders <0.5 mm for linear encoders> |

| Positioning tolerance | Adjustable for each position and for each axis Smart tolerance detection feature |

| Compatible tools | All tool with signals – electric or pneumatic Min required signals: ≪Fastening OK≫, ≪Tool Lock≫ |

| Communication | RS232 for bar code scanner , Ethernet |

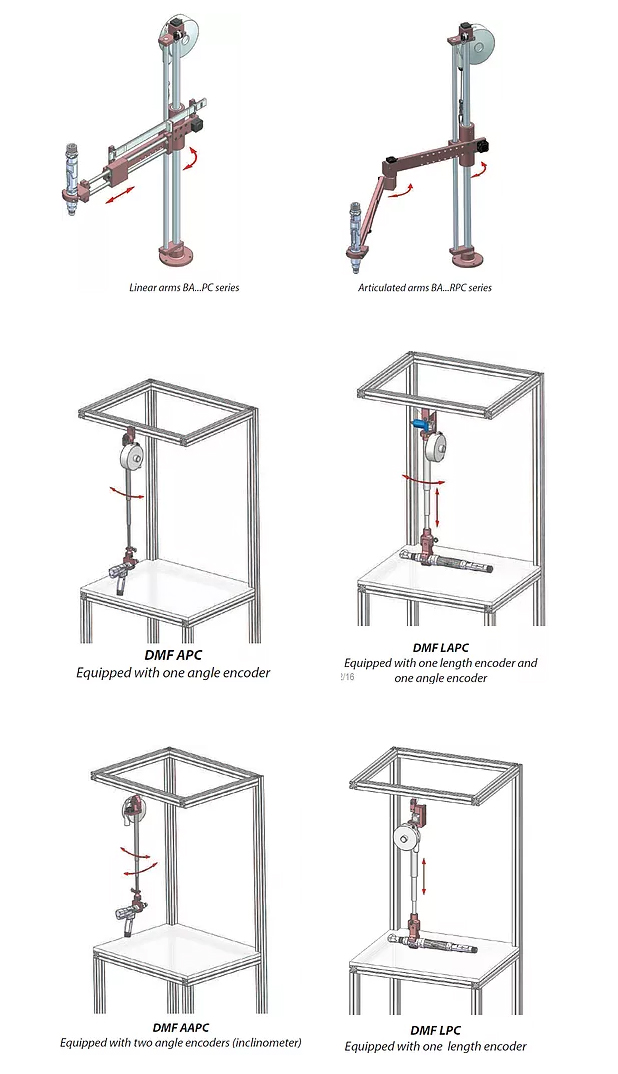

2. Position Arm

3. BIT SOCKET TRAY

Bit socket tray

Bit Socket Tray prevent mismatch error between bit to preset.

It guides the user on which bit to use.

[Master Mode] When change bit, preset change automatically.

[Slave Mode] When change the preset, connected hole’s LED is blinking.

It will improve productivity and reduce operator errors.

Use with MD series.

Main Feature

- It automatically guides you which BIT to use.

- Driver automatically lock when incorrect BIT use.

- Bit socket tray detect BIT through Magnetic or Color.

- I/O signal support.

- MODBUS communication support.

- Current status indication via LCD.

- Support setting of various mode.

Bit socket tray [Color]

- Color sensor detect bit’s color

- The color LED guide worker which BIT should be use.

- Color BIT reduce mistake by worker’s BIT mismatch.